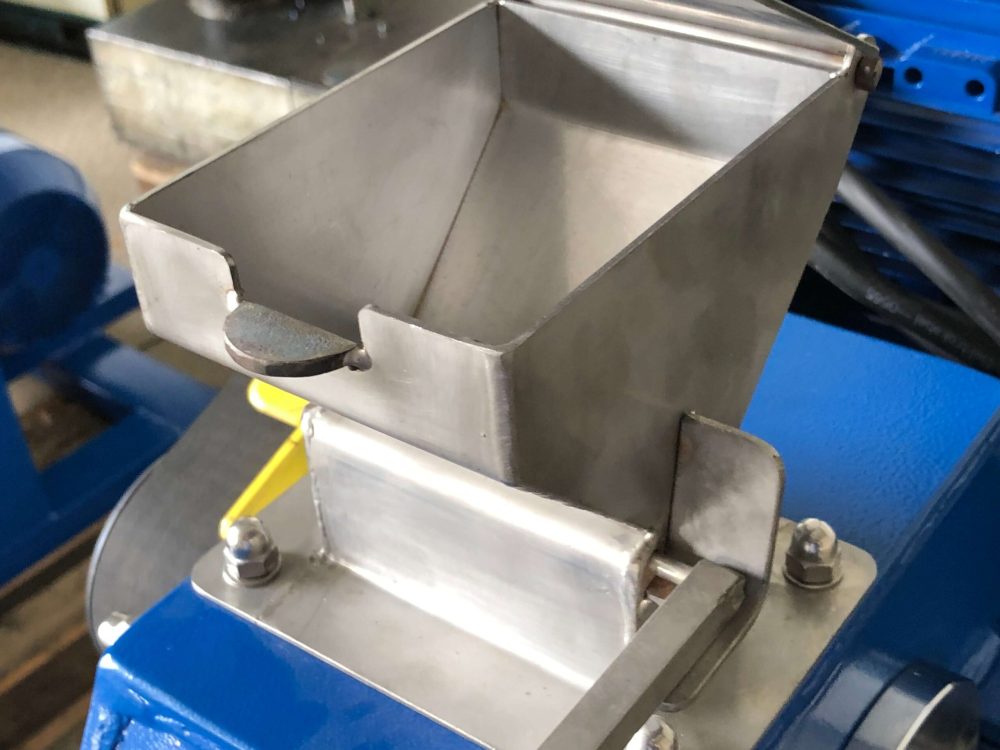

Hammer mills for efficient milling

Our hammer mills are indispensable for environmental laboratories, industry and universities in which hard, brittle, fibrous and hard-tough material must be pre-crushed quickly and reproducibly for subsequent fine grinding.

Your advantages at a glance:

- High throughput

- High degree of comminution

- High final fineness

- Interchangeable bottom sieves/ribs in different sizes

- Hammers available in different versions

- Safe and easy handling

- Easy to clean & easy access to the grinding chamber

- Built-in version available

- Combi conveying technology / sampling / grinding / sieving – “custom-made” on request

- Emergency stop button

- CE compliant

Applications for LITech hammer mills

Waste, batteries, construction waste, biomass, soil, CDs, precious metals (gold, palladium, platinum, rhodium, silver), electronic scrap, epoxy resin, earth, ores, animal feed, gypsum, glass, granite, wood, limestone, kaolin, cassettes, catalysts (metallic, ceramic), oxide ceramics, clinker, bone, coal, coke, plastics, metals, minerals, polystyrene, quartzite, X-ray images, slag, shavings, USB sticks, composite pieces, cement clinker and much more!

Available sizes and technical data

| Type | HM 120 | HM 200 | HM 300 | HM 400 |

|---|---|---|---|---|

| Max.Aufgabe* | <30x75mm | <30x150mm | <150x200mm | <200x350mm |

| Endfeinheit* | <1mm | <1mm | <1mm | <1mm |

| Durchsatz* | ~200kg/h | ~300kg/h | ~1000kg/h | ~2000kg/h |

| Antriebsleistung | 1.5kW | 1.5kW | 7.5kW | 7.5kW |

| CE-konform | JA | JA | JA | JA |

Order a free material test

We provide you with a free material test, depending on the application, material, numbers, etc. Tell us exactly what you require. We would be pleased to give you a call back to go over the specifics. Every test is conducted at our Fohnsdorf, Austria, internal technical center and laboratory. You cover the shipping costs of the material, we cover the remaining costs.

What our customers say about us